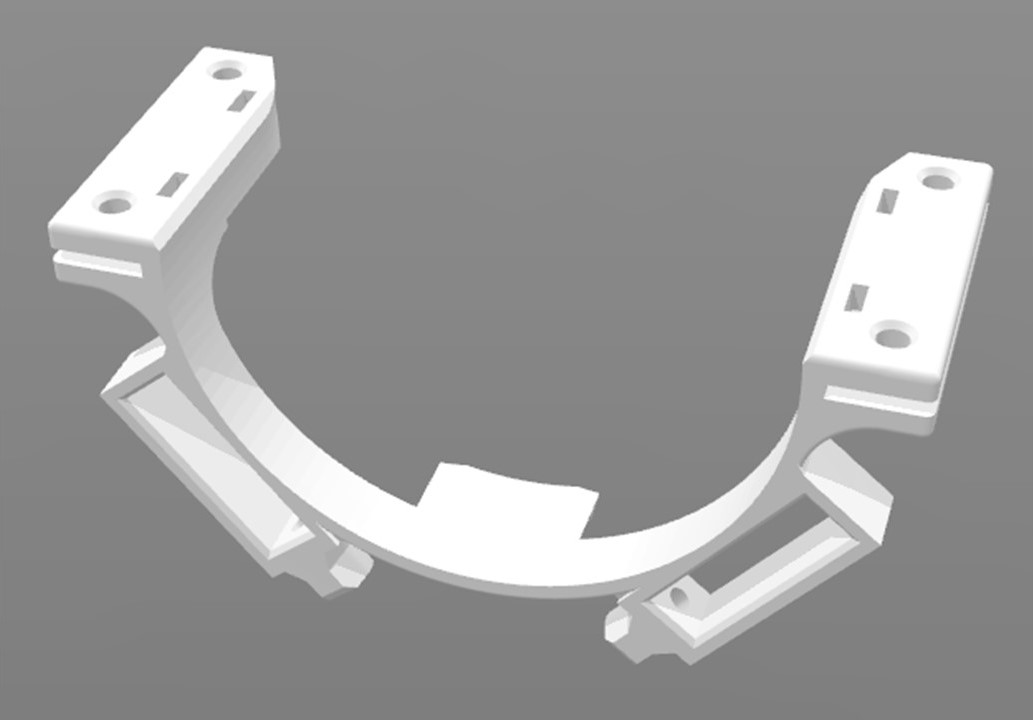

3D Printed parts (for Version 2.1)

You can download the original .stl files from the bottom of the page.

The 3D printed parts are for the maker/DIY type. We cannot recommend 3D printer settings due to the wide range of materials and printers.

The bottle plug was originally designed for multi jet fusion printing and its geometry is not idea for filament printing.

WARNING: 3D printing can produce fumes and poses other safety and health concerns. Use safety precautions when 3D printing.

ORIGINAL .STL FILES

Click on the image below to download the corresponding .stl file.

Please note that the rudder mount has been removed since it was for an obsolete bottle cap. Presently the new rudder mount is not available.